If you have electrically-powered lawn equipment, then you can tune this one out right away. You’re one of the lucky ones – you can just plug it in, hit a switch, and it’s ready to go. For those of us who use gasoline-powered equipment, many of us will get the chance to deal with a balky choke at some point in the course of working on our lawn.

What is a Choke?

Often referred to as a choke valve, it moderates the flow of air into the fuel-air mixture. Its primary use is to restrict the air flow when you are trying to start your piece of equipment. This restriction allows for more fuel to be pushed into the combustion chambers. This is important because small engines that are being started cold are poor when it comes to creating evaporation of gasoline.

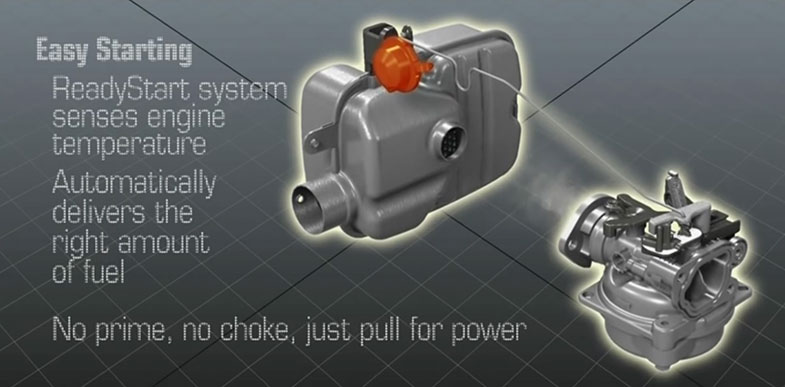

My neighbor has a Yard Machines push mower with a Briggs 550EX (model 09P702-0145-F1) with that stupid ReadyStart auto-choke feature. He brought it down saying it wasn't running right so the fastest thing to get him back in operation was to just throw a new carb on there (since they're only $22) and clean the old one at my leisure and keep for. Quality Briggs & Stratton Replacement Parts From Repair Clinic. Briggs & Stratton has a long history of providing dependable, quality products like small engines, generators power washers, and more. If any of your products have problems and don't work, you can find all of the Briggs & Stratton parts you'll need to fix most issues on your own. Troubleshooting tips for a Briggs & Stratton 190cc Model 120000 Quantum 675 Series Lawn Mower Engine. Released Feb 2011. For Toro 6.7HP Lawn Mower.

Problems with a Choke

Briggs 650 Ex Choke Cable Replacement

The most common issue that shows up with the choke system is flooding. If the engine is successfully started, leaving it at full choke for only a few seconds can cause too much fuel to enter into the combustion chamber. This will then cause the the engine to lock up and stall. Once the engine has been flooded, it can take quite a while for the fuel to drain out of the chamber to the point where the mower is easy to start once again. In the most extreme cases, you may need to even open up the engine to drain it and get it back into working order.

A second, fairly common problem is when the choke does not open and close properly or promptly. If your choke sticks, or doesn’t move properly, it can induce a flooding situation even if you follow the right steps for starting. A stuck choke can also prevent you from closing it fully to allow the engine to start properly. If it is not taken care of when it is only sticking slightly, the dirt can build up until the choke is stuck solid.

A Solution for Flooding

The Briggs & Stratton 190cc 675 Series Push Mower Engine produces 6.75 ft.-lbs. The 675 Series Engine is the more powerful version of the standard 650 Engine that Briggs and Stratton usually uses. It has a similar design as the 650, so if you are looking for repair guides to a 650 engine, these will work just as well.

You probably never succeed in starting the engine on the first pull of the cord. Instead of repetitively pulling the cord on full choke until it starts, pull until it seems that the engine is right on the cusp of starting. If you feel that the next pull will start it, move the lever to half-choke. This will allow some air to enter, and will reduce the likelihood of the engine flooding.

Fixing the Choke Opening and Closing

To keep the choke opening and closing properly, you’ll need to check and lubricate the choke shaft, as well as the choke linkage. Dealing with the choke shaft to improve movement is very simple – just spray carburetor cleaner along the shaft to loosen the grit. It will be knocked off during use, allowing the choke to return to working properly.

Briggs 650 Ex Choke Parts

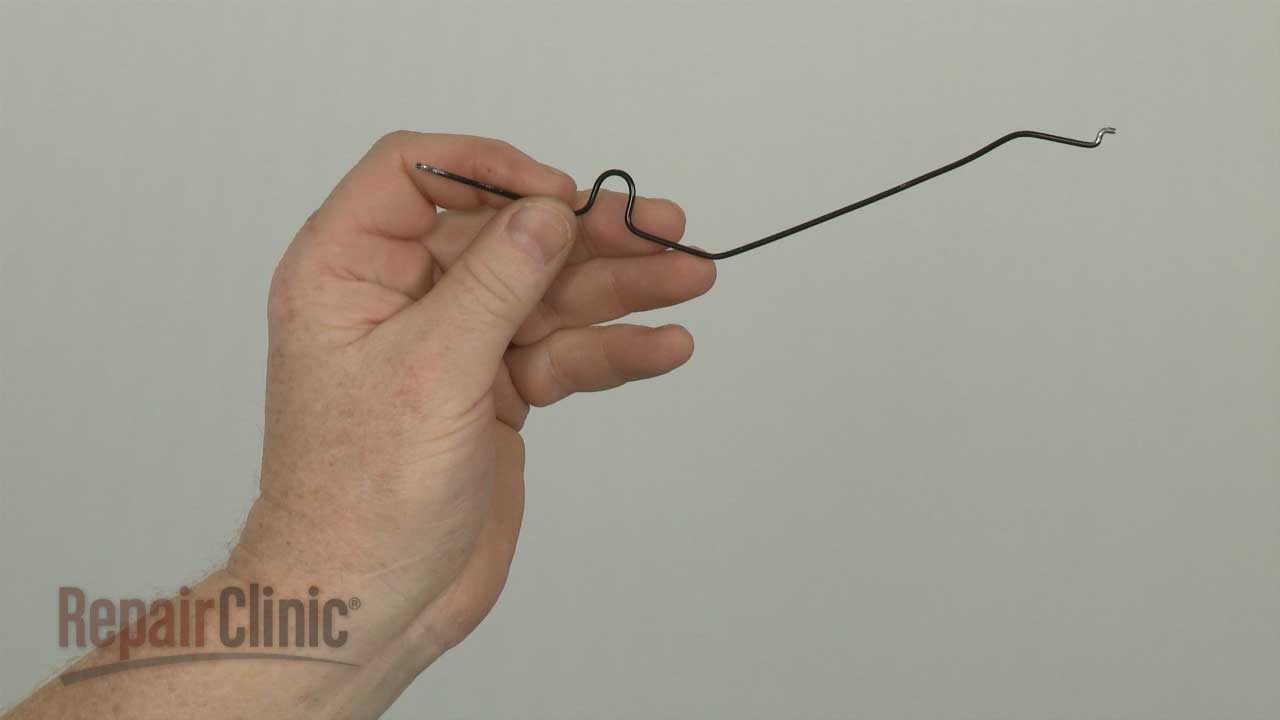

A second thing to check is the choke linkage. If this isn’t properly adjust, it may not close or open the choke as it is supposed to. By loosening the cable mounting bracket, as highlighted in the owners manual of a piece of equipment, the owner can move the choke lever and the cable casing to fix any gaps or problems with movement.

Briggs 650 Ex Choke Kit

Briggs 650 Ex Choke Tube

A choke is not some weird, difficult-to-understand part of the equipment. It has a simple function, simple operation, and really isn’t all that difficult to diagnose and repair. It just sounds a bit daunting. But anyone with the the proper screwdrivers and minor technical know-how can make sure a choke will never delay their work day again.

Briggs 650 Ex Choke Tubes

Related Posts:

Briggs 650 Ex Choke Tubes

These have a paper air cleaner, a plastic petrol tank and a plastic carburettor.

This series has two methods of cold starting

1, is a primer located in the air filter cover or beside the air filter.

2, is the ReadyStart system which has a bi metal spring located by the muffler which operates the choke on the carburettor.

The model-type-code can be found stamped into a plate just in front of the carburettor or on the right hand side stamped into the main engine block by the dipstick tube (for more information on how to find your engine numbers click HERE ).

With this information, you can use our interactive parts diagrams to find the parts you need.

Please find popular parts for your engine below or if you are unsure that you have the correct part, go straight to our interactive parts diagrams to find the correct part for your engine click HERE.